Cambodia Customer Feedback Use 15Ton/24H Rice Mill Plants

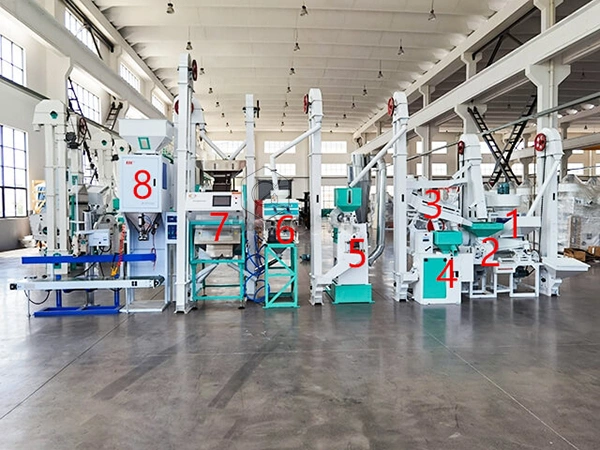

Cambodia customers order 15 Ton rice mill plants, including

1. Paddy clean and destoner machine, let paddy cleaner, also can protect the machine,

2. Paddy huller machine, let paddy be brown rice,

3. Paddy and brown rice separate machine, separate brown rice and paddy,

4. Rice mill machine, let brown rice be white rice,

5. rice polisher machine, make rice more beautiful,

6. rice grader machine, which can separate broken rice and whole rice,

7. Color sorter machine, which can separate different colored rice

8. A rice packing machine, can package rice into one bag 5kg,10kg,20kg,25kg,50kg, etc.

Above 8 machines, some machines, like the color sorter, and the rice packing machine can be removed as customer needs.

15 Ton rice mill machinery package:

15-ton rice milling machinery needs to use one 20ft container delivery, when you decide, let us know, and we also can check sea ship delivery freight for you.

Cambodia customer’s problem.

After the customer received 15 Ton rice mill machinery, gave us feedback, not only giving us feedback photos but also sending feedback video.

Cambodia customer’s problem When installing rice mill machinery,

1. The customer needs to dig a hole for the elevator, this is easier for the inlet paddy to machine,

2. Install elevator, add inside belt,

3. After installation, can add some paddy tests. after the test, they can use a rice mill machine.

When open rice milling machine needs attention:

When using a rice milling machine safety is important when using rice milling machine need use correct way.

1. Listen if there is any anomaly sound, like some anomaly grating and crash, when hearing any anomaly sound need to stop and check.

2. Attention inlet paddy, promise machine not blocking, also check paddy and brown rice separate machine’s husk. General is 85%-90%. also, check paddy and brown rice separate machine inlet is the same at each level.

3. Attention: when using the rice milling machine, first open all machines, and after checking, no problem, then can add Paddy.

How to use rice mill plants correctly.

Before opening the rice mill plants, check the rice screen, and rice mill blade, all parts’ screws are tight, the bearing needs add oil or not, check all machine’s working direction is right,

Second check paddy inside include nail or not, avoid damage machine inside. Third open the machine, first let the machine work for 5-10 minutes.no add paddy, if have no problem, then add the paddy.

Finally for protecting the machine, always need to check and clean the machine, then can let the machine use a long time, also need to change inside parts after some days.

When using a rice milling machine needs attention

1. choose a good quality rice milling machine, that can promise the machine to operate is safe, also is easy to operate and use, also promise each machine is suitable and can reach higher capacity.

2. When using the machine also need to check rice quality, and the environment, and promise to reach higher quality rice.

3. Protect and clean the machine, can let machine use longer, also need change inside parts, can let machine work more long time.

4. Promise machine and person safety.

Some problems when using rice mill machinery

1. machine vibrates, machine bearing is hot, Reason: The bottom screw is not tight. inside bearing need add oil or oil is more.

2. Have a strange sound, Reason: have nails inside the paddy, this also will damage the machine inside, also check screw is tight or not.

3. Rice mill machinery‘s blocking, Reason: Inlet more paddy, outlet pressure is more, the outlet is blocked by rice husk, or maybe paddy’s moisture is higher.

Final broken rice is more’s reason and solution:

1. The rice milling machine’s inside pressure is bigger, working time is longer, so reach more broken rice.

Solution A: adjust the rice mill blade and the rice screen’s distance to bigger, lower pressure, paddy has no more pressure, then the broken rate is decreased.

Solution B: Adjust the inlet, decrease the paddy inlet, increase the rice outlet, decrease the rice milling machine’s pressure, and decrease the rice’s broken rate.

2. The rice screens rotate fast, also damaging higher rice broken rate.

Solution: decrease rotates speed.

3. The paddy’s higher moisture, also will cause a higher price break rate.

Solution: decrease the paddy’s moisture.

When buying a rice milling machine our support‘s Payment method :

1. General we support 50% TT for the deposit, Balance before delivery.

2. Also can use Alibaba online payment,

3. Also support the use of Western Union, Paypal, etc. when you have any payment method want to use, can let us know.

How to Package rice milling machine

1. different rice milling machine type package is different, like 15 Ton combined rice milling machine and 25 Ton combined rice mill machine after the package is 2 package, the total is 12cbm. can use LCL is ok.

2. Like 15 Ton complete rice milling machine and 25 Ton complete rice milling machine need to use 20ft container delivery.

3. 30 Ton complete rice mill machine and 40 Ton complete rice mill machine need to use one 40ft container delivery.

4. give you suggestions, when you choose any type, can let us know.

Are You Ready to Start a Rice Milling Business, We Are a Professional Manufacturer of Rice Milling Machines? We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us.

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Phone/Whatsapp: 0086-18339828199