How to Choose a Combined Rice Mill Production Line?

As we know, a full set of automatic rice mill plants usually consists of the paddy cleaner destoner, paddy huller, paddy rice separator, rice mill, rice polisher, white rice grader, color sorter, and packing sealing machine. Also, some clients will require the thickness grader and length grader if they have higher rice quality requirements.

The common process of rice processing plant: Paddy cleaning--paddy designing--paddy hulling--paddy rice separating--rice milling--rice polishing--rice grading--color sorting-packing

The main Machines functions are as follows:

-1)The paddy cleaner is to remove the impurities such as the straw, and leaf, from the paddy

-2) The destoner is to remove the stone, clod, sand, etc from the paddy

-3)The rice huller is to remove the rice husk from the paddy to get brown rice

-4)The paddy rice separator is to separate brown rice from paddy ( brown rice will be into rice whitener, and paddy will be returned to rice huller).

-5)The sand roller rice whitener is to make brown rice into white rice...

-6)The iron roller rice mill is to make the white rice more white

-7)The mist polisher is remove the floating bran on the surface of the rice, and also plays the role of pre-gelatinization and gelatinization of the surface of the rice. The starch gelatinization makes up for cracks, to obtain a bright and clean appearance and improve the storage performance and commercial value of rice.

-8)The white rice grader is to grade the rice in a different grade.

-9)The color sorter is to select a different color from white rice.

-10) The packing machine is to pack and seal the finished white rice into 5-50kgs/bag

The different machines combined with different functions. Here we talked 15tons per day of rice milling equipment for example

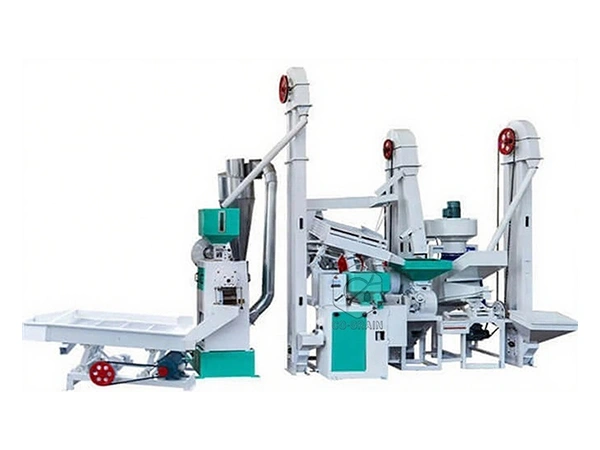

1) 15Tons per day rice milling equipment combined with one

This one is a combined one, including paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, and broken rice screen. It is the basic one which is most economic, suitable for small scale business. It is the most popular sale amount, for small farmers.

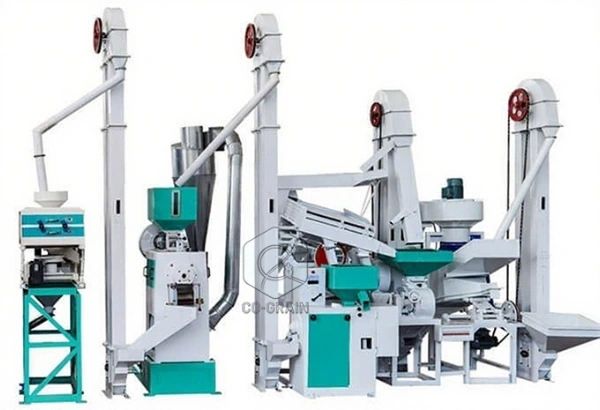

2) 15Tons per day of rice milling equipment combined one with the extra polisher

This one consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, rice polisher, and broken rice screen which to make the white rice more white if a buyer wants to make the rice more white as well doesn’t have enough budget, can choose this one.

3) 15Tons per day of rice milling equipment combined with an extra packing machine

This one consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, and packing sealing machine. After getting white rice, the rice can be packed into bags directly. Which can be convenient for into market.

4)15Tons per day of rice milling equipment combined one with extra polisher, white rice grader

This rice milling equipment consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, rice polisher, and white rice grader. This one can make the rice more white, as well the grader can separate the white rice into different grades.

5) 15Tons per day of rice milling equipment combined with an extra white rice grader and packing sealing machine

This one consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, white rice grader, and packing sealing machine, which grades the rice into different standards and packs them into bags.

6) 15Tons per day of rice milling equipment combined one with extra rice polisher and color sorter

This rice mill plant consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, rice polisher, and color sorter. It can make rice more white, as well can choose the bad and different colors from the white rice. The final rice quality is much higher.

7)15Tons per day of rice milling equipment combined one with extra rice polisher white rice grader and color sorter

This one consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, rice polisher, white rice grader, and color sorter. It can make rice more white, as well can choose the bad and different colors from the white rice, and also separating the white rice into different grades. The final rice quality is much higher.

8)15Tons per day of rice milling equipment combined one with extra rice polisher white rice grader and packing sealing machine

This one consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, rice polisher, white rice grader, and packing machine. It can make rice more white, as well as separate the white rice into different grades, then pack them into bags.

9) 15Tons per day rice mill machinery combined one with extra rice polisher white rice grader, color sorter, and packing sealing machine

This one consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, rice polisher, white rice grader, color sorter, and packing machine. It can make rice more white, as well can choose the bad and different colors from the white rice, and also separating the white rice into different grades. then pack them into bags.

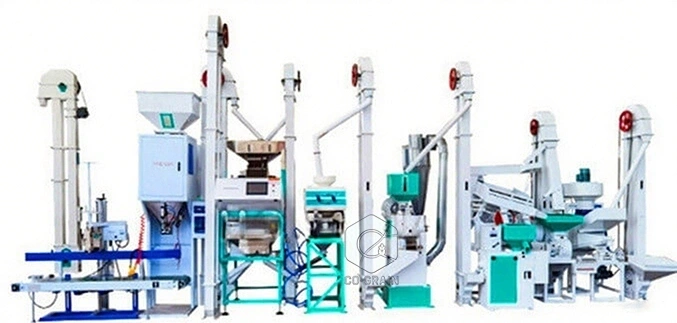

10) 15Tons per day of rice milling equipment combined one with extra rice polisher, mist rice polisher, white rice grader, color sorter, and packing sealing machine

This rice processing plant consists of a paddy destoner cleaner, rice huller, paddy rice separator, rice whitener, rice polisher, mist polisher, white rice grader, color sorter, and packing machine. It is the highest standard rice mill plant to make the highest quality of rice.

As a buyer, you can choose the rice mill machinery according to your requirements for the rice degree, your budget, and your factory size. We also can make the rice mill plant according to your needs.

Henan Co-Grain Machinery Engineering Co., Ltd. Established in the year 2000, it is a professional manufacturer and exporter of rice mill machine, rice processing machines, rice mill plant, rice processing plant, and parboiled rice mill plant. We can provide a unique overall layout design for the rice milling machine production line, customized rice milling machine products, and installation services according to the different needs of customers and site conditions. It integrates technology, manufacturing, and sales together.

Welcome Contact Us!

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Phone/Whatsapp: 0086-18339828199