How to Process Paddy to Rice with a Rice Mill Plant

Rice is one of the staple foods of people. It is a finished product that is processed by rice processing equipment (rice cleaning machine, stone removing machine, rice hulling machine, rice milling machine, rice grader, rice color sorting machine, packaging machine, etc). It is also one of the people's favorite foods.

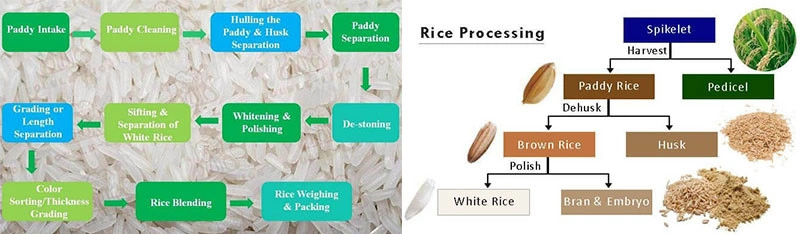

Rice Processing Process

The rice milling process in large commercial mills combines a number of operations that produce better quality and higher yields of white rice from paddy or rough rice.

Pre-cleaning, Rice Hulling, Paddy Separation, Rice Milling, Rice Polishing, Rice Polishing, Rice Grading, Rice Sorting, Rice Packing

The steps involved in rice processing are as follows:

Pre-Cleaning

When paddy enters a rice mill factory, it contains many foreign materials, such as straw, weed seeds, soil, rocks, and other inert materials. Therefore, when the rice is harvested and transferred to the rice processing plant, it needs to be cleaned in advance to ensure the normal operation of the machine and to obtain clean rice. The capacity of the rice pre-cleaner is usually 1.5 times the grinding capacity. In this step, you need Rice Cleaner, Rice Rotary Vibrating Screen, Rice Destoner, etc.

Rice Hulling

The next step is to remove the husk from the paddy to get the brown rice. After the husk is removed, the product is called brown rice and is ready for the milling process. The husk is removed by friction as the paddy grains pass between two abrasive surfaces that move at different speeds. After de-husking, the husk is removed by suction and transported to a storage dump outside the mill. Husk accounts for 20% of the paddy weight and an efficient husker should remove 90% of the husk in a single pass. Paddy graders and paddy cleaners are used to separate brown rice. In this step, you need rice huller machine.

Paddy Separation

The paddy separator separates unhusked paddy rice from brown rice. The amount of paddy present depends on the efficiency of the husker and should not be more than 10%. Paddy separators work by making use of the differences in specific gravity, buoyancy, and size between paddy and brown rice. In this step, you need Paddy Separator, we have Double Paddy Separator and Gravity Paddy Separator.

Rice Milling

This stage removes the bran layer of rice turning brown rice into white rice. In this step, you can get white rice. In this step you can use Vertical Roller Rice Mill Machine, Vertical Emery Roller Rice Mill Machine, Horizontal Iron Roller Rice Mill Machine, and Horizontal Emery Roller Rice Mill Machine. The rice mill process is the most important part of the complete rice mill plant.

Rice Polishing

The rice polisher machine is mainly used for the rice polishing process to further improve the rice's smooth finish. It’s a key piece of equipment for non-washing rice in rice processing plant. The surface of the rice is smoothened and it is given a shine by passing it through a series of rollers.

Rice Grading

It is a process in which broken rice is separated out and separated head rice into different lengths with Rice Length Grader, Rice Thickness Classifier. After polishing, white rice is separated into head rice, large and small broken rice, and “brewers” by an oscillating screen sifter. Head rice is normally classified as kernels that are 75−80% or more of a whole kernel. To attain a higher degree of precision for grading and separation a length or indent grader is used.

Rice Sorting

Discolored, yellow, and immature rice is removed in this stage adding value to rice by rice color sorter.

Packing

The finished product is then packed and stored to be delivered to valued customers by an automatic packing machine. The rice mill plant is also called a complete rice mill production line or rice mill factory, it includes all the rice process steps. You can tell us your needs and factory location. We can customize the layout of the rice milling plant and the design of the rice milling line according to your budget, factory location, and needs. We can supply 10-500T per day rice mill plants to you.

Henan Co-Grain Machinery Engineering Co., Ltd. Established in the year 2000, it is a professional manufacturer and exporter of rice mill machine, rice processing machines, rice mill plant, rice mill production lines, and parboiled rice mill plants. We can provide a unique overall layout design of the rice milling machine production line, customized rice milling machine products, and installation services according to the different needs of customers and site conditions. It integrates technology, manufacturing, and sales together.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Co-Grain Machinery Engineering Co., Ltd.

Email: info@ricemillplants.com

Phone/Whatsapp: 0086-18339828199